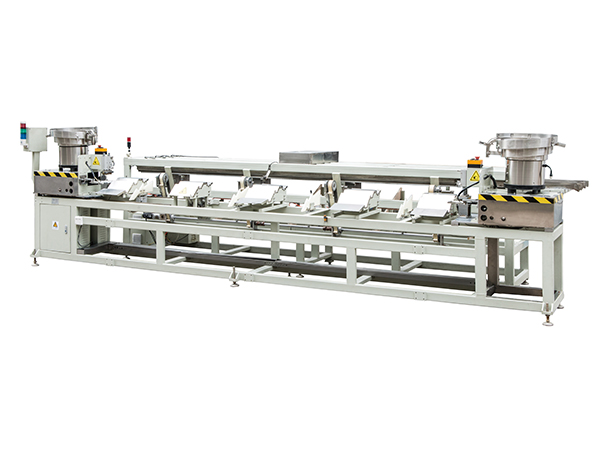

Automatic rewinding machine

张力锥度可调:在收卷过程中,由于卷径不断的变大,伺服电机需要的力矩是不断变化的,使用张力锥度功能,可以保证内外层的张力一致。

Accurate cutting position: it can receive the reset signal of the inkjet printer, and calculate the position that needs to be cut, so as to ensure the accurate position of the head and tail of each coil of pipe and prevent the error of the meter mark.

Compressed air automatic drainage: equipped with automatic drainage of air two-point combination to prevent the damage of pneumatic components caused by poor maintenance.

Rich communication interface: The system is equipped with EtherCAT,Modbus TCP industrial Ethernet interface, and RS485 interface, which has strong expansibility, and can also be easily integrated into ERP and other management software.

High degree of automation: winding device adopts servo motor tension control, unique invention patent, PLC built-in advanced winding algorithm, can ensure the regularity of winding.

Adjustable compactness of rewinding: it can adjust the compactness of tube coil in real time, so as to prevent the surface injury of tube caused by the tight expansion packing belt of tube during the follow-up pressure test.

Pipe break prevention function: when the system detects the broken pipe, it will stop automatically

Perfect system self-diagnosis function: up to more than 100 alarms can identify the error state of each component of the system (servo motor, remote IO, cylinder), as well as the operator's misoperation, and give the correct operation tips.

Automatic rewinding machine

Product introduction

Quanmao QMSJ series automatic winding machine is suitable for PE-RT, PE, PB, alu-plastic pipe and other plastic pipe and cable and other wire material winding and packaging, the machine can be used for automatic winding, automatic rewinding, automatic rewinding, automatic cutting and automatic binding of pipe, and equipped with automatic unwinding function. The machine adopts PLC+ man-machine interface + industrial Ethernet + encoder + remote IO+ full servo motor + cylinder control. The main key hardware adopts imported components, which can improve the automation level of equipment, reduce manpower and significantly reduce the production cost.