PP-R automatic packaging machine

-- Adopt high quality components, core components imported originally.

-- Equipped with automatic drainage air two-point combination to prevent damage of pneumatic components caused by poor maintenance.

-- Perfect system self-diagnosis function: the alarm device can identify the wrong state and wrong operation of system components, and give correct operation tips.

-- Rich communication interfaces: The system is equipped with EtherCAT,Modbus TCP industrial Ethernet interface, and RS485 interface, which has strong expansibility, and can also be easily integrated into ERP and other management software.

-- Customized design: to meet customers' modified requirements for product packaging.

PP-R automatic packaging machine

Product introduction

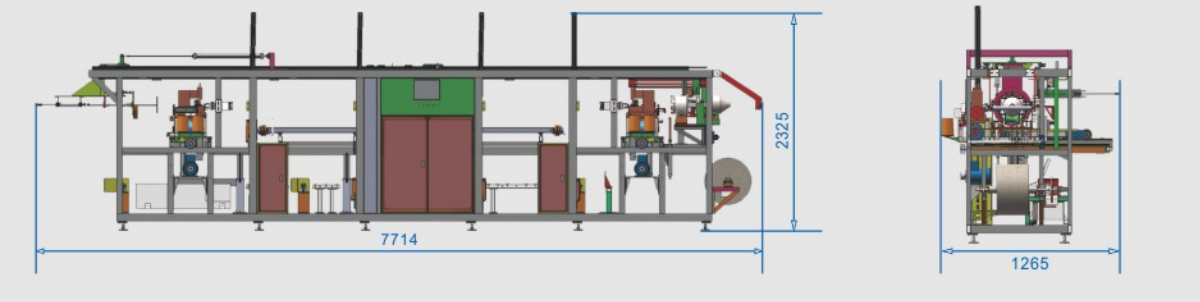

Quanmao QMBZ-32 series automatic packaging line is suitable for online automatic collection and packaging of PP-R pipe, and can be used together with capping machine to form a complete set of PP-R pipe production line. Can be used for Φ20 - A 32mm, length of 3-4 meters of PP-R pipe packaging. The machine is composed of inner bag packing machine and outer bag packing machine. The inner bag packing machine undertakes capping machine and outer bag packing machine, and realizes the capping machine to complete capping and counting and sorting completed inner bags of pipe sleeve. The outer bag packing machine undertakes the inner bag packing machine, and realizes the function of counting the pipe material for inner bag packing and covering the outer bag. The inner packing bag adopts heat sealing at both ends, and the outer packing bag can adopt sewing sealing or wrapping film sealing two sealing forms. The whole machine adopts HMI+PLC+ photoelectric sensor + solenoid valve + cylinder + servo motor control, with counting function, communication using industrial Ethernet (speed 10M). High degree of automation, significantly reduce production costs.

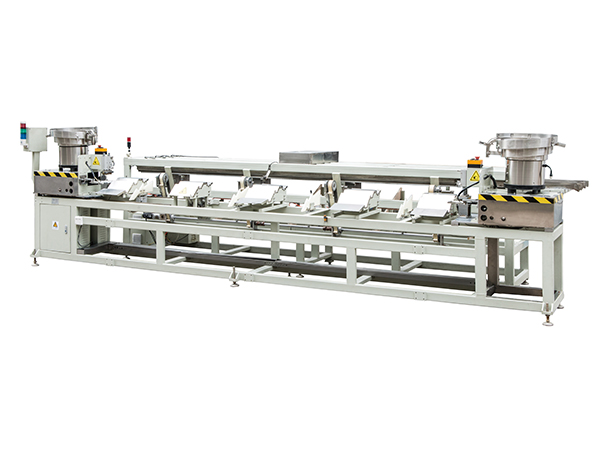

Inner bag packing machine

Undertake capping machine and outer bag packing machine. Realize the capping machine to complete capping and counting and sorting completed the inside of the pipe bag function. The whole roll of packaging bag is rounded through the opening device of bag mouth. The bag clamping trolley returns to the original position and clamps the bag tightly. When the photoelectric switch sends back the signal that the pipe quantity meets the packaging requirements, it blocks the action of the cylinder and lowers the pipe into the rectifying groove. The lifting cylinder lifts the pipe to the specified height, and the bagging trolley pulls the pipe until the bagging is completed. Push the cylinder and the heat sealing mechanism at both ends in turn to complete the bagging work of the inner bag. Lift cylinder back to initial position. The conveying motor starts to work and transfers the bagged pipe to the outer bag packing machine.

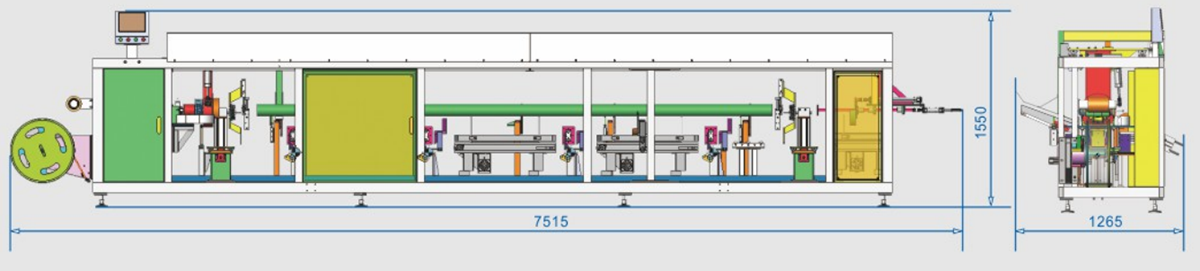

Outer bag packing machine

Undertake inner bag packing machine, realize the function of inner bag packing material counting and outer bag covering. When the pipe transported from the inner package is counted, the turnover mechanism acts to turn the pipe into the integral groove at one time, and the lifting cylinder acts to lift the pipe to the bagging height. The bagging car completes the bagging work, and then the edge pressing cylinder and the vacuum sucker start to work. After placing the certificate, the flanging cylinder moves to complete the shaping of the bag mouth and the fixation of the certificate. At this time, the sewing motor of the sewing group drives the sewing machine to sew the bag mouth which has been folded. At the same time, the motor is sent into the sewing machine. The lifting cylinder is lowered, and the finished packaged pipe is placed on the output belt. The output motor and the cylinder move in turn, and the finished packaged pipe is output to the storage rack.